Linear Vibrating Screen Application in Food and Chemical Industry

Application

1) Chemical industry: resin pigment, medicine, grease, paint, palette, etc.

2) Organic fertilizer industry.

3) Plastics industry.

4) Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

5) Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc.

6) Paper-making industry: coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

7) Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide, etc.

8) Mechanical industry: casting sand, powder metallurgy, electromagnetic material and metal powder, etc

linear-vibrating-screen-test running video

Working Principle

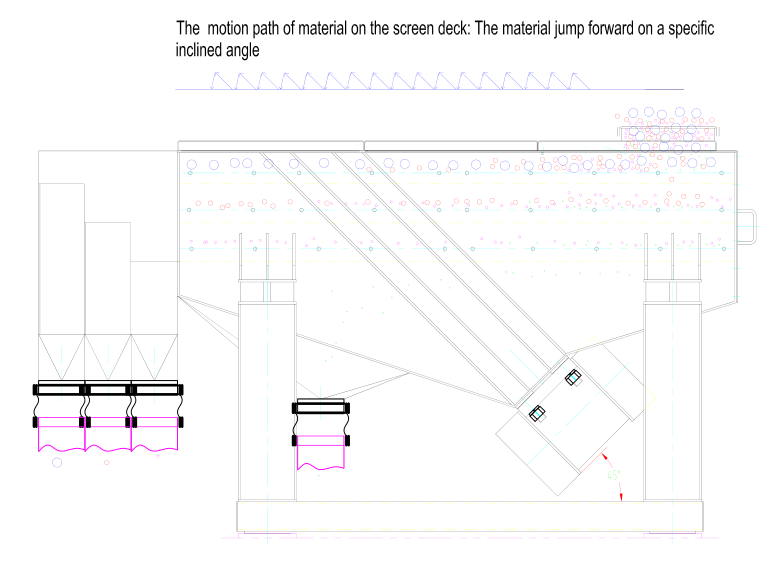

The screen box of the linear vibrating screen makes self-synchronous rotation along the opposite direction depending on double vibration motors, which makes the whole linear vibrating screen machine supported on damper do linear motion. Materials go through the screen loosely and move forward after falling into the screen box from inlet and then finish the separating work finally.

The linear vibrating screen machine is composed of screen box, vibration motor, damping system and chassis. The screen box consists of chute, roof, screen frame, screen plate (mesh), wire gauze.

Material Moving Trajector