Application and Working Motion of the Tumbler Vibrating Screen

Publisher: Tumbler Vibrating Screen Date: Sep 26, 2016

The highly developed M&Y tumbler vibrating screen have set the standard for fine and ultra-fine screen technologies of all types of dry bulk material.

M&Y tumbler vibrating screen features 7 different machine sizes ranging in diameters from 800mm-2600mm, currently offers the widest product range of tumbler screener available on the market worldwide.

tumbler-screening-machine

Industrial Applications

ï¬ Chemicals/Pharmaceuticals

ï¬ Aggregates and Ores

ï¬ Food

ï¬ Waste/Recycling

ï¬ Plastics

ï¬ Metallurgy

ï¬ Wood/Biofuels

ï¬ Ceramics

ï¬ Feed

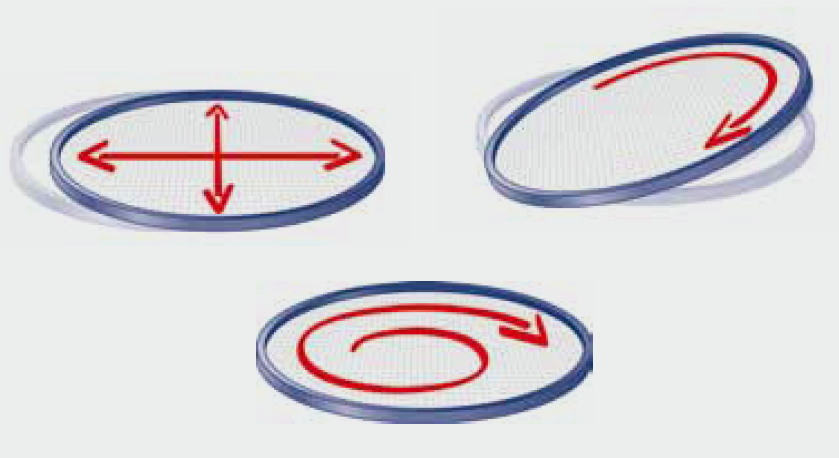

Unique tumbling type motion

The adjustment of the machine in response to the product to be screened provides an exactly defined three dimensional eccentric motion pattern with radial and tangential inclination.

During operation of the tumbler screener the radial inclination causes the product on the screen to move from the centre towards the edge of the screen while the tangential inclination leads to a circular motion of the product on the screen. The combined impact of both of these forces causes the product in a helical motion of upon the surface of the screen and therefor to a relatively long retention time. This provides an optimized result on fraction separation while at the same time minimizing the amount of remaining outsize particles.